Regular DSLR cameras have a fixed sensor with a lens specified to illuminate the entire sensor circle.

This set up is fine for CMOS sensors that can has lots of pixels, however, Apollo has an InGaAs area sensor.

InGaAs sensors are difficult to make with lots of pixels. If we wanted to make an infrared reflectography camera with as many pixels as a regular DSLR, it would require an array of sensors, which is not cost effective.

To overcome this problem, Apollo has one 128×128 pixel sensor, housed on a mechanical stage that incrementally scans over the entire imaging area. The mechanical stage is a precision assembly which is essential when positioning the sensor. The sensor is cooled to reduce the ‘noise floor’.

Each tile has a slight overlap to align perfectly when Apollo’s software automatically stitches the tiles together to create one seamless mosaic of images.

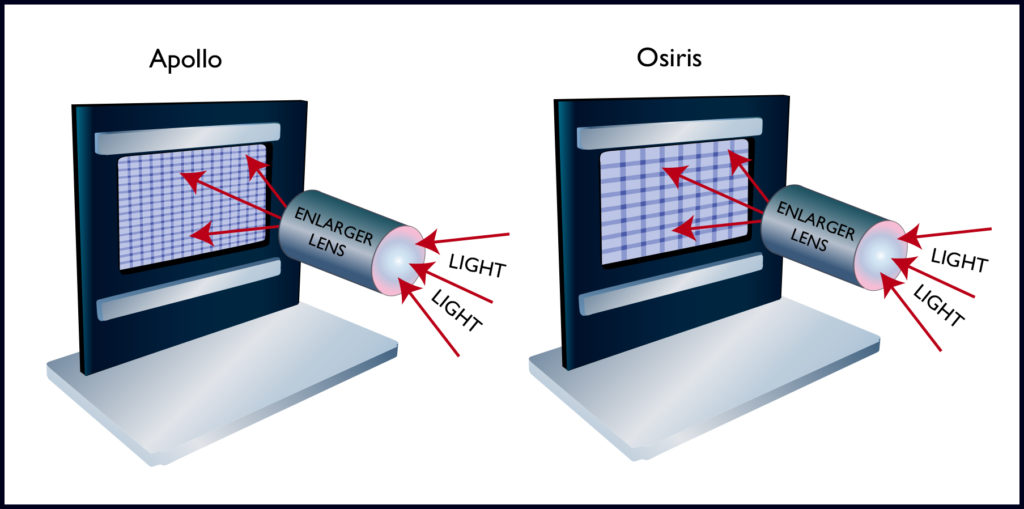

Approximately 1600 tiles that are used to construct the whole image – in comparison with Osiris which scans 64 tiles.

Another significant difference between a regular DSLR camera and Apollo and Osiris is the lens.

Opus cameras use a bespoke enlarger lens, to enlarge the light by projecting the image onto a surface about the size of a postcard. The sensor then scans over that postcard area to gradually record the image.

The lens journey starts with the high quality optics being made in Japan and assembled in the United States, and is produced entirely bespoke to Opus Instruments.

Infrared photography at the National Museum of Norway. Photo Annar Bjorgli/The National Musuem.

The Apollo camera has fomented new research in art history and English literature

Ashmolean Museum, Oxford University